Commercial & Industrial Dustless Concrete Shot Blasting Services Solutions

The Power of Concrete Shot Blasting in Surface Preparation

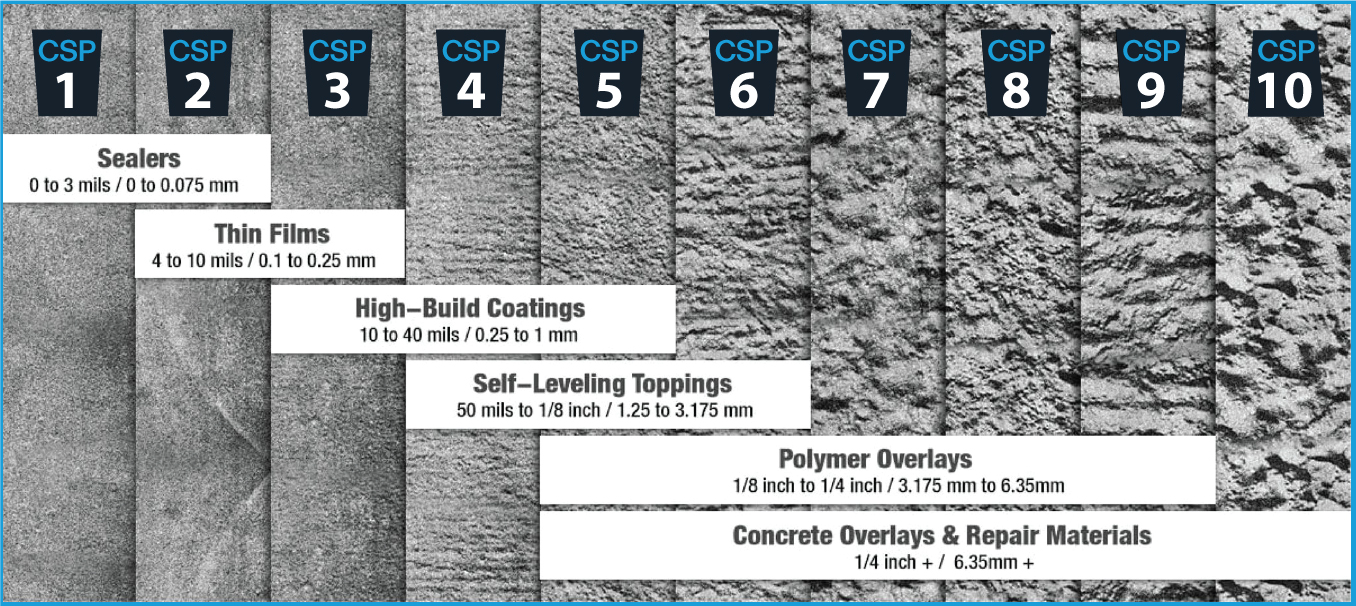

In concrete surface preparation, the Concrete Surface Profile (CSP) is the cornerstone of a successful coating or flooring project. Achieving the correct texture ensures superior adhesion, durability, and the long-term performance of coatings and overlays. With its ability to create a higher CSP profile, shot blasting is the preferred method for projects where coating success is critical.

Our advanced shot blasting services take surface preparation to the next level. Utilizing the state-of-the-art Blastrac 1-10DS Shotblaster paired with a high-powered vacuum system, we deliver a virtually dust-free experience. This innovative approach not only ensures cleanliness but also maximizes precision and efficiency.

Why Choose Shot Blasting?

- Creates higher CSP profiles for better coating adhesion.

- Delivers a cleaner, more durable surface for overlays.

- Minimizes airborne dust for a safer, more efficient work environment.

Shot blasting is a game-changer in the world of concrete surface preparation, offering a reliable and efficient alternative to traditional grinding methods. With our expertise and cutting-edge equipment, your project is in the best hands, ensuring surfaces that perform and endure.

Blastrac 1-10DS

Shot blasting is one of the fastest and cleanest methods of mechanical abrasion, making it an ideal solution for a wide range of projects. It’s especially effective in sensitive areas where dustless, chemical-free methods are required, such as:

- Food preparation and manufacturing facilities

- Clean rooms

- Spaces with sensitive inventory or machinery

Our advanced Blastrac 1-10DS Shotblaster is at the core of our shot blasting services, combining cutting-edge technology with unmatched efficiency to deliver flawless results.

How Shot Blasting Works

The Blastrac 1-10DS uses recycling wheel blast technology, which propels steel shot or grit at high velocity onto the concrete surface. This process is driven by centrifugal force from a high-speed wheel with paddle-type blades, ensuring a precise and thorough cleaning process.

Key steps include:

- Coating Removal: Abrasive impacts the surface, dislodging coatings and debris up to 8 mils thick. For thicker coatings, diamond grinding is the preferred method.

- Recycling Process: Abrasive and debris rebound into a reclaim chamber, where reusable materials are separated from dust and waste.

- Dust Collection: Dust and debris are transported to a high-powered collector via airflow, ensuring a clean and environmentally friendly process.

Why Choose Shot Blasting?

- Fast and Efficient: Significantly reduces preparation time for large areas.

- Precision Technology: Produces a smooth, clean surface ready for coatings or overlays.

- Environmentally Friendly: Dustless operation minimizes cleanup and reduces airborne particles.

Whether preparing a sensitive workspace or tackling a commercial flooring project, shot blasting offers a reliable and efficient solution to meet your needs. With our expertise and state-of-the-art equipment, you can expect superior results every time.

Services

Driveway Sealcoating

Garage Floor Coating

Asphalt Maintenance

Commercial Flooring

Corporate Office

11262 Kilmer Rd

Edison, NJ 08872

Phone

NJ (732-524-7757

VA (804) 234-3180