Professional Concrete Floor Surface Preparation Services

Dustless Grinding, Shot Blasting & Adhesive Removal for Commercial, Industrial & Retail Spaces

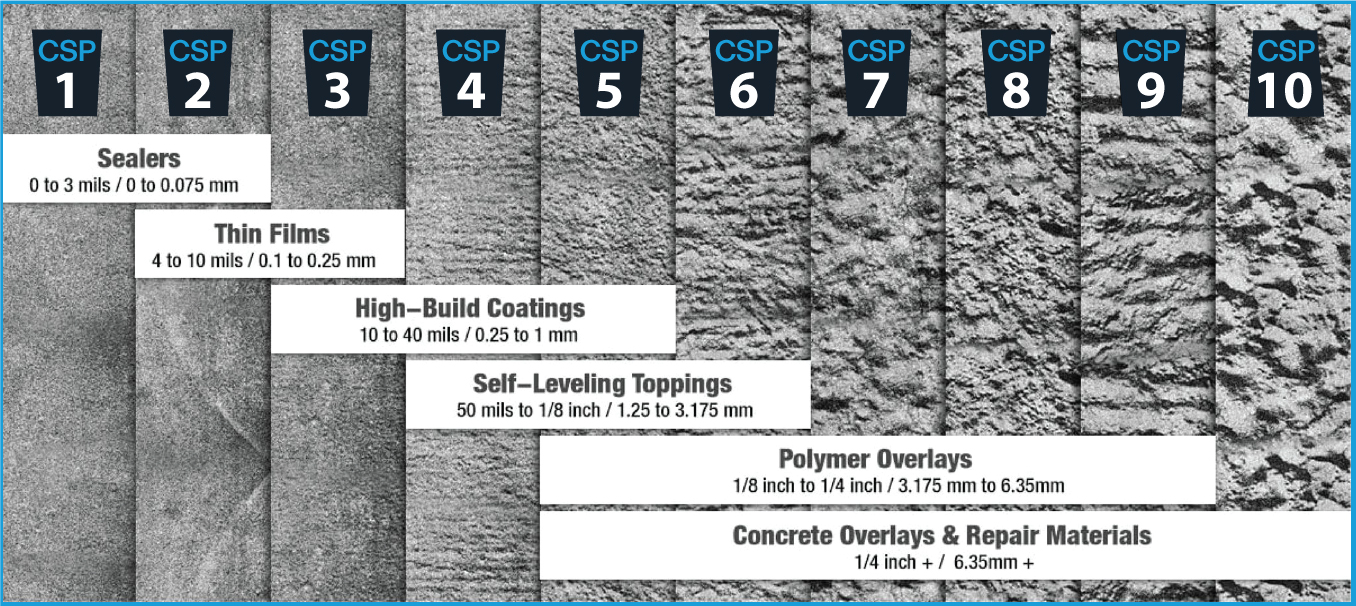

Proper surface preparation is the cornerstone of any successful commercial flooring project. Achieving the correct Concrete Surface Profile (CSP)—measured on a scale from 1 to 10—is critical for ensuring adhesion and long-term durability. At River City Sealcoating, we specialize in preparing concrete substrates to the precise CSP level required, setting the foundation for resilient, aesthetically pleasing, and long-lasting flooring solutions.

Comprehensive Surface Preparation Services

From adhesive removal and thin-set elimination to contaminant cleaning and surface profiling, our experienced team uses state-of-the-art equipment to ensure your concrete is ready for its next phase. We understand the unique demands of commercial spaces such as showrooms, warehouses, and retail environments, and we tailor our approach to meet the specific needs of each project.

Why Choose Us?

- Expertise in achieving the ideal CSP level for any coating or resurfacing system.

- Advanced techniques like dustless grinding and shot blasting for efficient, clean preparation.

- Commitment to precision and quality for every commercial flooring endeavor.

Whether you’re rejuvenating a high-traffic showroom or preparing a warehouse for heavy-duty use, we’re here to ensure your investment stands the test of time. With our focus on meticulous preparation, your flooring project will start with a solid foundation, ensuring long-term success.

Step-by-Step Guide to Professional Surface Preparation

The following concrete surface preparation guidelines are designed to assist owners, design professionals, specifiers, and contractors in achieving optimal results. Surfaces intended for sealers, coatings, mortars, or resurfacers must be structurally sound, thoroughly cleaned, and free from any materials that could compromise adhesion. Proper surface preparation is a critical factor in ensuring the immediate and long-term performance of applied polymer or cementitious flooring and wall systems.

Step 1: Inspection Of Concrete Substrate

Inspection of the concrete substrate is a critical first step in determining its condition, soundness, and suitability for surface preparation. This includes identifying contaminants, assessing moisture vapor emissions, and evaluating the best methods to meet the specific requirements of the owner or their appointed representative. A thorough evaluation ensures the selection of the appropriate tools and equipment to achieve optimal results and long-term performance.

Step 2: Removal & Replacement of Non-Durable Concrete

Before installing a polymer system, it’s essential to address any weak or deteriorated concrete. Non-durable sections must be removed and replaced with cementitious repair mortars, polymer concrete, or an engineered concrete mix design. For compatibility with selected polymer sealers, coatings, or linings, always refer to the system Bulletins and Technical Data Sheets.

Surface Preparation for Bonding

When bonding fresh concrete to existing concrete, proper surface preparation is key. This involves methods such as scarifying, abrasive blasting, needle scaling, high-pressure water jetting (5,000–45,000 psi), or steel shot blasting. A low-modulus epoxy bonding agent should be applied at 80 square feet per gallon (20 mils WFT). Place fresh concrete or mortar while the epoxy is still wet, ensuring proper adhesion. For lightweight concrete, a second coat of epoxy may be required if the first coat is readily absorbed.

Concrete Mix Considerations

Fresh concrete should have a low water-cement ratio (w/c) of no more than 0.40. For latex-modified concrete mixtures, verify compatibility with the epoxy by installing a test patch or conducting a pull-off test through an independent laboratory.

Step 3: Decontamination of the Concrete Surface

Proper decontamination of concrete surfaces is essential to remove oils, grease, wax, fatty acids, and other contaminants that could interfere with adhesion. This can be achieved through methods such as:

- Detergent scrubbing with heavy-duty cleaners or degreasers

- Low-pressure water cleaning (less than 5,000 psi)

- Steam cleaning

- Chemical cleaning

The effectiveness of these techniques depends on the depth of contaminant penetration, which is influenced by the contaminant’s viscosity, the concrete’s permeability, and the duration of exposure.

Special Considerations for In-Use Facilities

In facilities like food processing plants, contaminants such as animal fats, oils, blood, cleaning agents, and microbes often penetrate deep into the concrete due to the extensive use of water. Even after surface preparation (e.g., shot blasting), contaminants may remain embedded, making the concrete appear clean but unsuitable for a strong bond.

Testing for Sound Concrete

To ensure the concrete is adequately decontaminated, perform a pH test using distilled water and pH paper. Alkaline concrete typically has a pH range of 11 to 13. If the pH drops to 10 or lower, additional preparation is required. In cases where contaminants cannot be fully removed, consider:

- Removing and replacing the contaminated concrete

- Using a special oil-tolerant epoxy system to achieve proper adhesion

The Importance of Thorough Preparation

Effective decontamination ensures a strong bond for coatings, toppings, or repairs, reducing the risk of failure and extending the lifespan of the concrete surface. Proper testing and preparation are vital for achieving optimal results in any facility.

Step 4: Creation of Surface Profile

The creation of a surface profile is essential to ensure polymer-based products bond securely to concrete. Achieving this profile involves selecting the appropriate methods, tools, and materials based on several factors, including:

- The type of surface (e.g., floors, walls, ceilings, trenches, tanks, or sumps)

- The specific system being installed

- The type and thickness of the polymer system

- The service conditions the structure will face

Regardless of the method or tools used, the goal is to create a surface that enables the polymer system to form a strong mechanical bond with the concrete. This ensures long-term durability and performance.

Understanding Surface Profiles

The surface profile is a measure of the average distance between the surface’s peaks and valleys, as seen in a cross-sectional view of the concrete. The required degree of profile depends on the type of polymer system being applied and the service conditions the structure will endure.

Proper surface profiling is critical for ensuring the longevity of the polymer system and the success of the overall project, whether it’s for heavy-duty industrial use or more general commercial applications.

Concrete Surface Profile (CSP) Chart

SHOT BLASTING

Shot blasting is one of the cleanest and fastest methods of mechanical abrasion, ideal for preparing concrete surfaces in sensitive or specialized environments. This dustless, chemical-free technique is perfect for areas such as:

- Food preparation and manufacturing facilities

- Clean rooms

- Spaces with sensitive inventory or machinery

- Environments requiring minimal disruption

How Shot Blasting Works

Shot blasting utilizes recycling wheel blast technology to clean and prepare surfaces efficiently. Steel shot or grit is propelled at high velocity onto the concrete surface using centrifugal force generated by a high-speed wheel with paddle-type blades. This impact dislodges coatings and debris, effectively cleaning the surface.

Key features of the process include:

- Coating Removal: Best suited for removing coatings up to 8 mils thick. For thicker coatings, diamond grinding is recommended.

- Abrasive Recycling: Dislodged debris and abrasives are reclaimed into a chamber where reusable abrasive is separated from dust and debris.

- Dust Collection: Dust and debris are transported via airflow to a dust collector, ensuring a clean and environmentally friendly process.

Advantages of Shot Blasting

- Fast and Efficient: Shot blasting can significantly reduce preparation time for large areas.

- Environmentally Friendly: Dustless and chemical-free, making it safe for sensitive environments.

- Precise Results: Creates a clean, profiled surface ideal for coatings and finishes.

Whether preparing a standard flooring job or working in specialized areas, shot blasting offers unmatched efficiency and cleanliness, ensuring your surface is ready for the next stage of your project.

Precision Diamond Grinding for Superior Concrete Preparation

For surface preparation requiring exceptional precision and adaptability, diamond surface grinding stands out as the method of choice. While shot blasting is efficient for coatings up to 8 mils, diamond grinding offers unmatched performance for thicker coatings and more challenging projects.

At River City Sealcoating, we utilize the advanced HTC 800 Planetary Surface Grinder to deliver precise, consistent, and efficient results across a wide range of applications.

The Power of Planetary Grinding

Unlike the high-velocity steel shot method used in shot blasting, the HTC 800 employs a planetary grinding system with multiple grinding heads rotating in tandem. This system ensures a smooth, even surface finish, making it ideal for:

- Food preparation and manufacturing facilities

- Clean rooms

- Areas near sensitive inventory or machinery

- Locations requiring dustless, chemical-free preparation methods

Unmatched Versatility

With interchangeable diamond pads and specialized tooling, our grinders can handle any challenge, including:

- Thick thin-set removal

- Glue and adhesive removal

- Mechanical profiling

Whether preparing for a coating system or achieving a specific surface texture, the HTC 800 delivers tailored solutions to meet your project’s exact requirements.

Dust-Free and Environmentally Friendly

The HTC 800 is designed with an integrated dust collection system to maintain a virtually dust-free environment during operation. This system effectively separates waste materials and dust from reusable abrasives, ensuring a clean and eco-friendly process.

Why Choose Diamond Grinding?

- Handles Thick Coatings: Perfect for coatings exceeding 8 mils.

- Precision and Consistency: Ideal for achieving specific surface profiles.

- Clean and Safe: Dustless technology ensures a clean workspace, even in sensitive environments.

- Versatile Tooling: Adaptable to a wide range of surface preparation needs.

Whether you’re working on a manufacturing floor, a commercial facility, or any space requiring meticulous preparation, diamond surface grinding provides the precision, cleanliness, and reliability your project demands.

Durable Joint & Crack Repairs for Long-Lasting Concrete Surfaces

Proper surface preparation is the cornerstone of successful joint and crack repairs. Without it, even the best materials—no matter how well mixed and applied—are likely to fail. To ensure durability, all concrete substrates must meet or exceed the compliance standards of ACI, ASTM, ICRI, NACE, and SSPC.

Critical Preparation Steps

- Remove surface contaminants and deteriorated concrete.

- Roughen and clean the surface to allow proper adhesion.

- Smooth any mortar splatter, protrusions, ridges, or sharp projections to ensure a uniform application.

Application of Elastomeric Membrane Systems

Elastomeric membranes, such as internally flexible epoxy systems, require consistent dry film thickness to withstand drying shrinkage, thermal movement, and provide a seamless seal. For effective application:

- Seal control joints, contraction joints, construction joints, and cracks with a compatible flexible sealant.

- Apply 20 mils of the selected elastomeric membrane, extending at least 6 inches on either side of the joint or crack.

This method ensures a smooth, durable, and long-lasting repair, effectively bridging imperfections and maintaining performance in high-stress environments.

Expansion joint filled with our clear, flexible, resilient, 100% solids polymer two-component material.

Surface crack filled and re-profiled with our low viscosity, extremely fast setting two-component hybrid polyurea repair material designed to penetrate and “weld” cracks together.

Services

Driveway Sealcoating

Garage Floor Coating

Asphalt Maintenance

Commercial Flooring

Corporate Office

11262 Kilmer Rd

Edison, NJ 08872

Phone

NJ (732-524-7757

VA (804) 234-3180